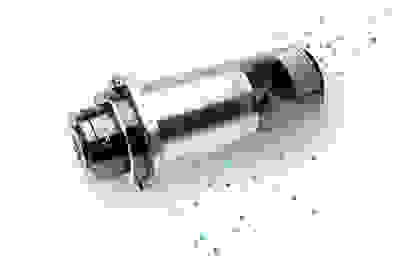

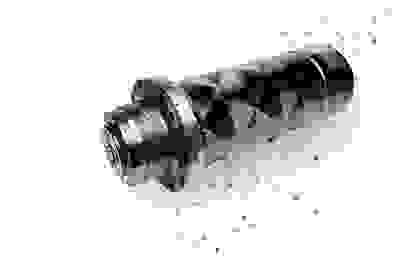

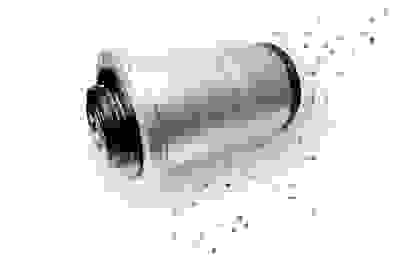

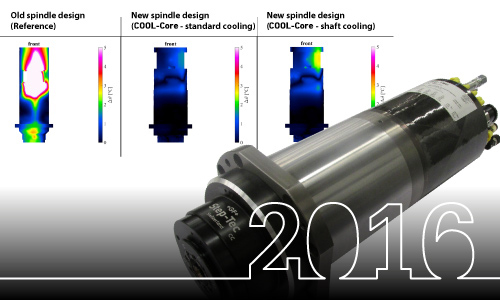

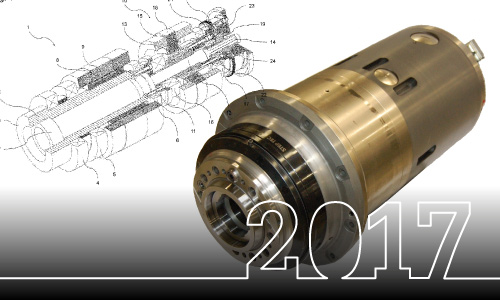

In today’s complex economy, strategies for increasing sales, maintaining product quality and saving cost can stand in competition. To maintain an edge over emerging markets, machine tool builders need innovative solutions. Step-Tec motor spindles improve machine performance – hence application quality – while reducing cost of integration.

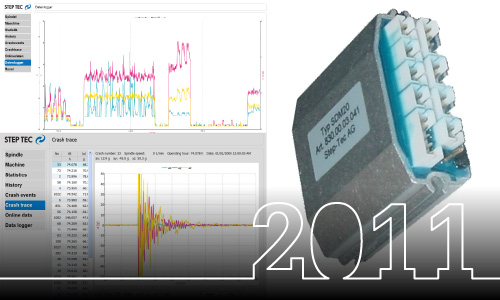

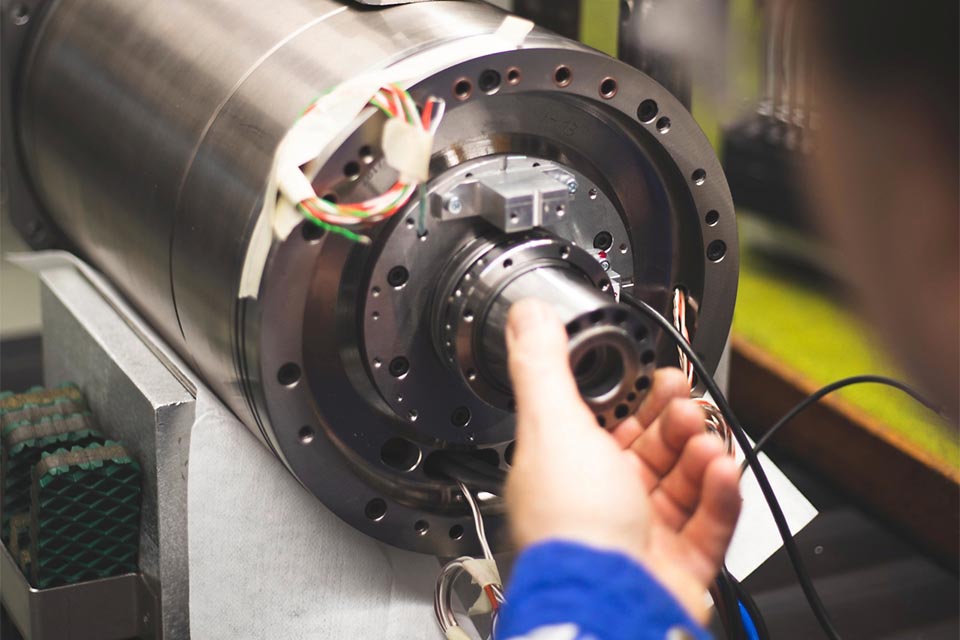

Step-Tec's solutions for high-frequency motorized spindles empower machine tool builders to respond to new manufacturing requirements. Our spindle platforms enable engineers to design best-in-class products with maximum machine uptime, thanks to outstanding service and technical know-how, as well as easy access to accessories and software packages.

For more specific information about Step-Tec spindles, choose your industry or your spindle platform.